The 5-Gallon Plastic Bucket: A Packaging Staple that Never Goes out of Style

Plastic buckets are having a moment. Miniature versions are selling like collectibles, shoppers are scouring stores for the latest bucket drops, and creative promotions have turned everyday pails into necklaces or tied to events like National Popcorn Day. What was once a purely functional item is suddenly a cultural conversation piece.

For over 50 years, we’ve believed plastic pails deserve recognition for the role they play behind the scenes. From construction and agriculture to food service, chemicals, and consumer goods, plastic pails, including the widely used 5-gallon plastic bucket, quietly support essential supply chains around the world. Their versatility, durability, and efficiency make them one of the most popular packaging formats in the world.

While many people are discovering how useful a plastic bucket can be, few stop to consider where these pails begin their journey.

From Pellets to Packaging

Most round plastic pails are manufactured using an injection molding process with either high-density polyethylene (HDPE) or polypropylene (PP) resin. Resin pellets are melted, blended with additives like colorant, and the liquid mixture is injected into the plastic pail mold. Once the material cools and hardens, the mold opens and a rigid, durable container is formed.

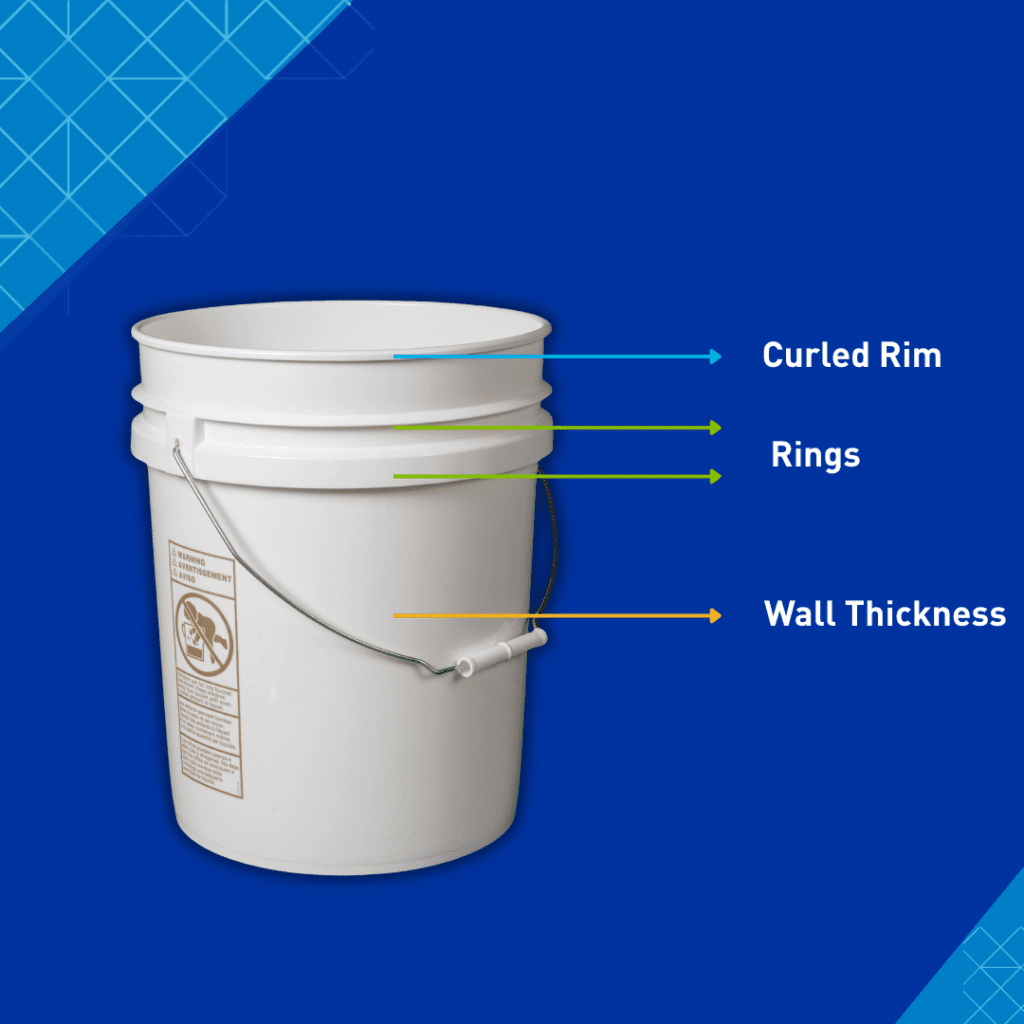

Every element of a plastic pail is intentionally engineered. Design details are not aesthetic afterthoughts; they are functional features developed to meet real-world requirements.

- The curled rim at the top of the pail makes the pail sturdier and helps the lid snap on tightly, so it doesn’t pop off or leak when the pail is carried or stacked.

- The rings around the pail act like support beams, helping the pail keep its shape, prevent it from bulging when it’s full of product, and support stacking.

- The thickness of the pail helps ensure it’s strong enough to withstand daily use and transportation without cracking.

Together, these features work in concert to deliver strength, reliability, and usability, proving that even the simplest packaging formats are the result of thoughtful engineering.

Evolving Plastic Bucket Designs to Meet Industry Trends

While the round, 5-gallon plastic bucket may be the face of the industry, customer needs have driven innovation far beyond a single size and format. Today, plastic pail solutions include round, square, and rectangular designs, each offering unique advantages.

At the same time, sustainability and regulatory requirements are reshaping how pails are designed and produced. Increasingly, regulations are driving the adoption of post-consumer recycled content (PCR) in packaging and increasing pressure to make packaging curbside-ready for processing through existing municipal recycling streams.

As a result, modern plastic pail innovation is no longer just about shape or size. It’s about balancing functionality, regulatory compliance, sustainability goals, and circular economy principles.

A Broad Portfolio for Real-World Demands

Plastic pails are more than a trend for us, they’re a core competency built over decades of expertise. Our portfolio includes one of the industry’s most comprehensive selections of plastic buckets, available in multiple sizes, shapes, materials, and colors to meet a wide range of needs. Paired with state-of-the-art decoration capabilities, these solutions help transform everyday packaging into a meaningful brand touchpoint.

So, as plastic buckets enjoy their moment in the spotlight, we remain focused on what matters most: delivering high-performance plastic pails that work reliably day after day, long after the trend fades.