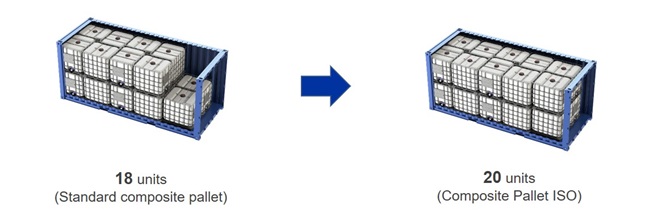

Mauser Packaging Solutions is pleased to introduce an IBC solution that features a new composite pallet designed to maximize volume and loading efficiency of Intermediate Bulk Containers (IBCs) on 20-ft ISO shipping containers.

As the export market continues to grow and evolve, efficient use of space and freight is increasingly important. The newly designed ISO pallet, modeled after the trusted Mauser Packaging Solutions composite pallet, features a lower stacking height, improving the loading process and increasing the total number of IBCs shipped per 20-ft container by 11% - from 18 to 20 units. The new ISO composite pallet design will save customers one ISO shipping container for every 200 IBCs shipped!

Traditionally, door height restrictions block the use of two potential IBC spaces near the container opening and require that IBCs are loaded individually and double-stacked once inside the container. The new pallet design accommodates deeper nesting of IBCs, allowing the shipper to load IBCs stacked two high, improving loading efficiency more than 50%, and eliminating the two unused spaces near the container opening.

The new composite pallet is impact-resistant, designed to withstand rugged handling, accessible by forklifts from all four sides, and compatible with the standard Mauser Packaging Solutions composite pallet.

Click here to download the product flyer.